Chairman's Speech

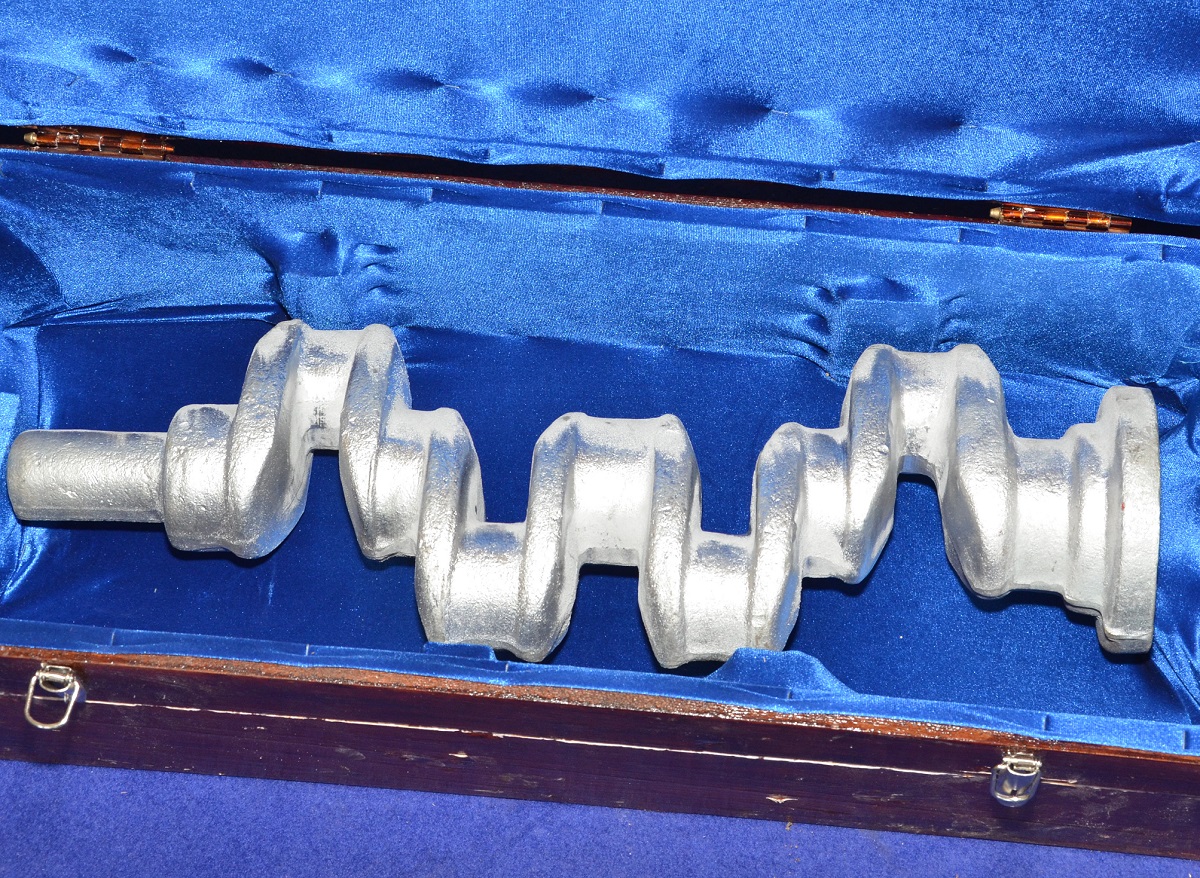

Al Nasr forging industry works according to the holding company’s strategy in institutional development for individuals and equipment with the aim of improving the overall performance of the company through, continuing to obtain new marketing sources, and striving towards improving product quality, and searching for new product manufacture as per the market demand, and working on Maximizing profitability by increasing worker and equipment productivity while rationalizing consumption and working continuously towards qualifying workers technically and administratively to keep pace with all developments and competition.

Social Responsibility

Nasr forging company pays great attention to the surrounding environment as it plays its full role towards it in preserving it by adhering to environmental conditions and taking all measures that it maintains through environmental protection projects where the company has: – By switching to gas and electricity instead of diesel to reduce exhaust and air pollution, and this through the installation of electrical induction furnaces To reduce noise pollution, the company turned pneumatic hammers into hydraulic and canceled the air pressure station The company also constructed an industrial sewage plant for recycling wastewater and used it in gardening and green planting We always strive to obtain quality certificates in environmental compliance and environmental management (ISO14001)

Believing in the return of the commitment to the safety and occupational health of the economic and environmental workers, the company has committed to the tasks of prevention and obtaining an industrial security certificate (ISO45001)

ABOUT US

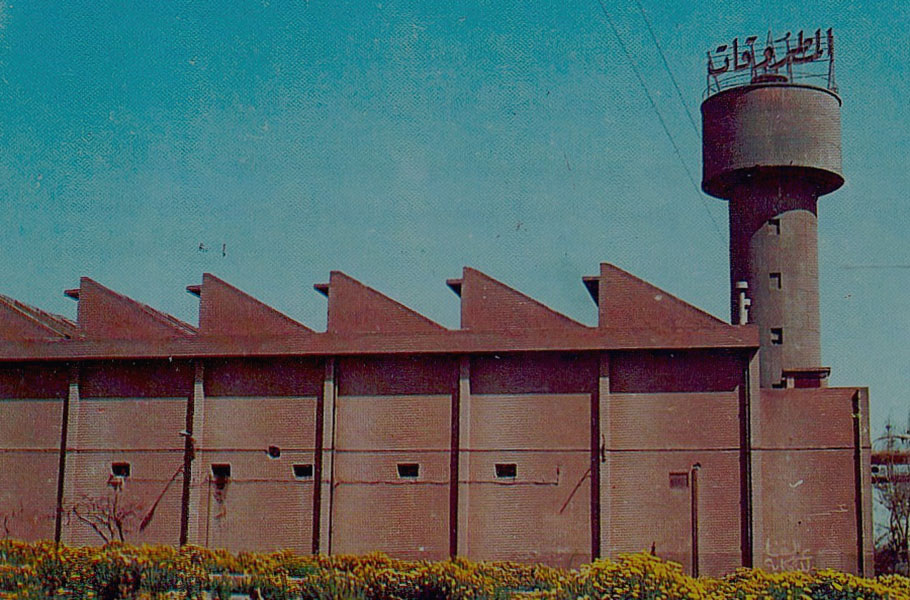

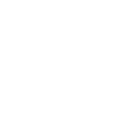

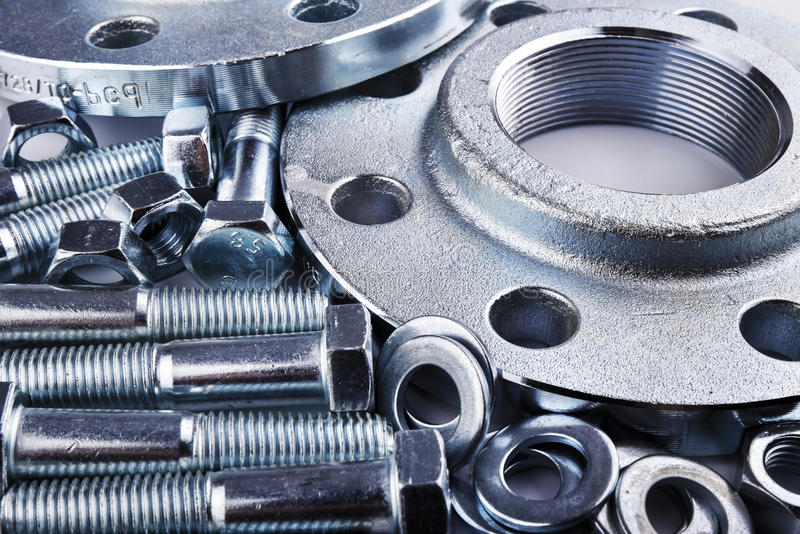

Al-Nasr forging company is considered the largest forging plant in Egypt and middle east it was established in 1960 to produce forged steel for feeding the following industries:legimus euripidis ea.

العربية

العربية

cialis free 30 day trial

cialis free 30 day trial

cialis free 30 day trial

tadalafil research liquid

tadalafil research liquid

tadalafil research liquid

price for sildenafil 20 mg

price for sildenafil 20 mg

price for sildenafil 20 mg

generic brand viagra

generic brand viagra

generic brand viagra

safe place to buy viagra

safe place to buy viagra

safe place to buy viagra

sildenafil 20 mg sale

sildenafil 20 mg sale

sildenafil 20 mg sale

tadalafil 40 mg for sale

tadalafil 40 mg for sale

tadalafil 40 mg for sale

cialis effective time

cialis effective time

cialis effective time

cialis headache

cialis headache

cialis headache

tadalafil 5mg

tadalafil 5mg

tadalafil 5mg

rybelsus trulicity

rybelsus trulicity

rybelsus trulicity

rybelsus generic

rybelsus generic

rybelsus generic

rybelsus weight loss success stories

rybelsus weight loss success stories

rybelsus weight loss success stories

rebellious diabetes pill

rebellious diabetes pill

rebellious diabetes pill

pfizer zithromax

pfizer zithromax

pfizer zithromax

what is ciprofloxacin

what is ciprofloxacin

what is ciprofloxacin

cephalexin foods to avoid

cephalexin foods to avoid

cephalexin foods to avoid

cephalexin used for

cephalexin used for

cephalexin used for

cephalexin para que sirve

cephalexin para que sirve

cephalexin para que sirve

where can i buy cialis

where can i buy cialis

where can i buy cialis

levitra dosing instructions

levitra dosing instructions

levitra dosing instructions

is levitra still available

is levitra still available

is levitra still available

valium internet pharmacy

valium internet pharmacy

valium internet pharmacy

best online pharmacy alprazolam

best online pharmacy alprazolam

best online pharmacy alprazolam

neurontin 100 mg for nerve pain

neurontin 100 mg for nerve pain

neurontin 100 mg for nerve pain

can you drink alcohol with augmentin

can you drink alcohol with augmentin

can you drink alcohol with augmentin

do i need to check blood sugar while taking metformin

do i need to check blood sugar while taking metformin

do i need to check blood sugar while taking metformin

how long does lyrica stay in your system

how long does lyrica stay in your system

how long does lyrica stay in your system

is amoxicillin 875 mg a strong dose

is amoxicillin 875 mg a strong dose

is amoxicillin 875 mg a strong dose

lisinopril adverse effects

lisinopril adverse effects

lisinopril adverse effects

prednisone dosage for adults

prednisone dosage for adults

prednisone dosage for adults

how long does it take for lyrica to work

how long does it take for lyrica to work

how long does it take for lyrica to work

ampicillin stock plasmid

ampicillin stock plasmid

ampicillin stock plasmid

glucophage mp.pl

glucophage mp.pl

glucophage mp.pl

trihexyphenidyl pediatric dose

trihexyphenidyl pediatric dose

trihexyphenidyl pediatric dose

zymaxid vs biaxin

zymaxid vs biaxin

zymaxid vs biaxin

clarithromycin 500 uses

clarithromycin 500 uses

clarithromycin 500 uses

albendazole dosing

albendazole dosing

albendazole dosing

mesalamine induced acute intolerance syndrome

mesalamine induced acute intolerance syndrome

mesalamine induced acute intolerance syndrome

online paper

online paper

online paper

buy customized essays

buy customized essays

buy customized essays

pay someone to write my dissertation

pay someone to write my dissertation

pay someone to write my dissertation

best website to buy an essay

best website to buy an essay

best website to buy an essay

cheap essay service

cheap essay service

cheap essay service

related literature in research

related literature in research

related literature in research

research paper sources

research paper sources

research paper sources

paper writers

paper writers

paper writers

ibict

ibict

ibict

paperpal login

paperpal login

paperpal login

help with writing an essay

help with writing an essay

help with writing an essay

write my papers

write my papers

write my papers

pay someone to do my essay for me

pay someone to do my essay for me

pay someone to do my essay for me

help with college essay

help with college essay

help with college essay